WIP at home: Thursday 16th April

As promised last week, here are some photos and text describing some of the work in hand, despite the lockdown. This week Roger Bye has put together Part one of a report on the Tyers tablet machine's restoration.

Over the past few years the railway has been fortunate in procuring Tyers Token Machines from a variety of sources. These machines, as many readers will know, are used to control the issue and receipt of multiple single-line tokens where train operations are more complex than the single token section we have at the moment.

These machines date from a time where brass and wood were the norm for instrumentation. Most of the machines are in poor condition both externally and internally. Over the years Don and Trevor (until his untimely death in 2018), worked on the restoration of these machines.

In recent years Malcolm has taken up the challenge of restoring the machines and is continuing to work on them at home during the current Coronavirus induced crisis.

1. A completely refurbished Tyers Token Machine. These consist of a very heavy cast base and frame incorporating a drawer which gives access to the tokens. This drawer is unlocked by the “electronics” housed in the wooden cased upper part of the machines. No solid-state electronics here...

2. ... all is done with mechanical levers and rods operated by relays. Here is a past view of a machine being dismantled by Don and Trevor...

3. ...and another with Don working on a partially dismantled machine while Dave examines a reproduction token.

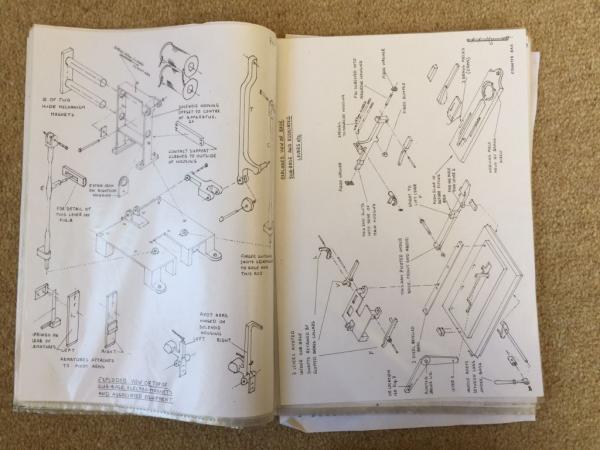

4. There was no handbook available – that is until Don created one - with beautifully drawn detailed exploded views of the mechanism. These drawings have facilitated the work of Malcolm and others.

5. The base of these machines - seen here - is massive and weighs about 15kg.

6. To facilitate moving the base and ultimately the machine around at home without injury to him, wife or house Malcolm constructed a trolley….

7, 8, 9, 10 & 11. The timber construction and veneer of the wooden cases had suffered badly…

12. This required drastic action. All the old varnish and paint was stripped in the kitchen sink!!

13. Then the case was taken apart carefully, removing the old veneer from the wooden slats that formed the curved profile of the case top. The mouldings around the base were also removed. Sections of the original mouldings were recovered with a view to using them as a pattern to replace damaged sections.

14. Where possible the original fixing screws were retained and cleaned up

With everything in pieces it was now time to start the reconstruction phase!!

See next week’s instalment – no binge watching here!

Please feel free to comment below.

Comments

Tyler's Token Machine refurbishment.

Absolute work of art, well done to all involved.

Tablet Machine Overhaul

Some fine work there. I have some material and knowledge on these I'd like to share with you Please get in touch. NickWellington, S&T Engineering Manager, Kent & East Sussex Railway